Voor milde stalen krimp

Ontvang de meest recente Prijs| betaling Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Min. orde: | 1 Set/Sets |

| vervoer: | Ocean,Land |

| Haven: | Dalian,Qindao |

| betaling Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Min. orde: | 1 Set/Sets |

| vervoer: | Ocean,Land |

| Haven: | Dalian,Qindao |

merk: Lijiaans

Material: Steel

Moq: 1 Set

certificaat: Other

Type: Tunnel Formwork

Oppervlakte behandeling: Painted Or As Customer Requirement

Toepassing: Tunnel Engineering

Tolerance: Gb Or As Customer Requirements

Design: Provided By Li Jian

| Verkoopeenheden | : | Set/Sets |

| Pakkettype | : | Volgens het verzoek van klanten |

The file is encrypted. Please fill in the following information to continue accessing it

High strength ultra toughness low shrinkage concrete

What is Plastic Shrinkage Cracking? This phenomenon happens when the concrete is still plastic, soon after pouring. They're an all too common type of shrinkage cracks in concrete slabs, generally emerging parallel to one another. The cracks are usually shallow in depth and rarely cross the slab perimeter. What Causes Plastic Shrinkage Cracks? Though unattractive, concrete plastic shrinkage cracks seldom affect the durability and/or strength of floors or pavement. But it's important to understand the key causes to minimize future development. Rapid Surface Moisture Evaporation This is the most common cause of plastic shrinkage cracking. It occurs when the surface moisture evaporates at a faster rate than the bleed water can rise to the surface for replacement. Generally, a meniscus forms between the aggregate and cement particles when the water recedes underneath the concrete surface. This causes the development of a tensile force between the surface layers. Once the surface begins to set and develops an adequate tensile strength, cracking won't occur. But if rapid surface evaporation occurs when the concrete is still plastic, cracks forms as the concrete continues to set.

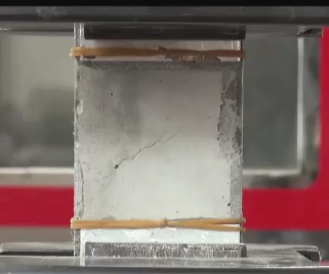

A-ecc is an ultra-high continuity cement-based composite with high strength, high ductility, high toughness and high durabilit.y through material design and adjustment, and can show strain hardening and multi-point cracking in tension

Typical application of traditional ECC —Meiyuan bridge, Japan

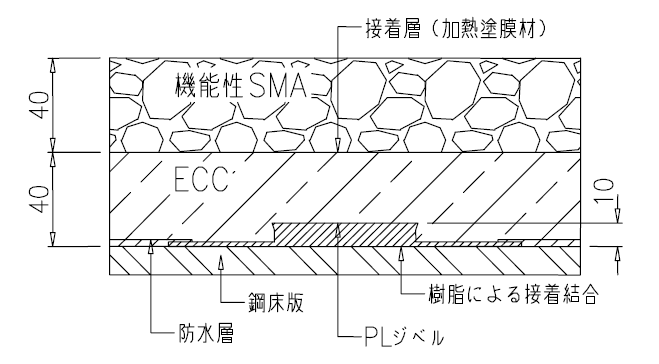

Pavement structure type

The ECC layer is pva-ecc;

PVA fiber volume content 2.0%;

Waterproof and crack resistant: the pavement layer is ECC layer (40mm) + wearing course

|

Product model |

A-ECC-30 |

A-ECC-50 |

A-ECC-60 |

A-ECC-70 |

|

compressive strength/MPa |

30 |

50 |

60 |

70 |

|

tensile strength/MPa |

3.0 |

4.0 |

4.5 |

4.8 |

|

Ultimate tensile strain/% |

≥3.0 |

1.2 |

1.0 |

0.8 |

|

Flexural strength/MPa |

9 |

12 |

14 |

16 |

|

Drying shrinkage/ |

≤600 |

≤400 |

||

|

Resistance to chloride ion penetration/C |

3500 |

3000 |

2000 |

1000 |

|

Frost resistance |

F200 |

F300 |

F300 |

F300 |

|

It can realize early strength and fast hardening, the setting time is adjustable from 30min to 6h, and the strength of 3H / 28d is ≥ 0.5 |

||||

High toughness

Effectively solve the problem of pavement cracking caused by inconsistent stress and deformation caused by different thickness of pavement concrete

Low shrinkage

Effectively solve the problem of pavement cracking caused by inconsistent shrinkage between beam and pavement

Good adhesion

Effectively solve the pavement quality problems caused by falling off of reinforcement, extrusion of reinforcement mesh and ponding

Homogeneous and isotropic

Effectively solve the phenomenon of "bottom sinking" of reinforcement mesh

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.